Pontiac Bonneville 1999 uses one serpentine belt to connect all components, to escape a bent shaft. The difficult part about replacement of a serpentine belt is a layer pad to an engine mount, is bound with a belt and should be removed. As soon as the layer pad is removed, replacing a belt will occupy some minutes. The serpentine belt diagram can be received from the owner's manual or from an engine compartment to guarantee belt spasms properly optimum performance data.

1. Guarantee that the car is switched off, and keys out of ignition. Open a cover for access to an engine compartment.

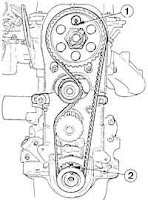

2. Follow a belt to the base of the engine a crankshaft pulley. The pulley intertwines through a layer pad. The layer pad should be removed.

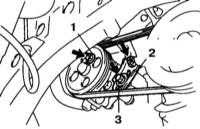

3. Unscrew a bolt from a layer pad with bit torx. Pull out a layer pad from a way. Separate a wire, by unsnapping a connector.

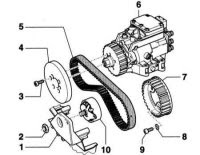

4. Ослабьте a pulley of the tensioner with a socket wrench. Push away the tensioner to slacken a belt.

5. Move a belt from pulleys and from an engine compartment. Replace with a new belt. Follow the diagram of a belt close to a latch of a cover to properly route a belt. Don't place a belt round a tensioner pulley while picnic isn't full.

6. Push away a pulley of the tensioner with a socket wrench. Place a belt on a pulley and slowly exhaust a pulley. The belt will strain, as the pulley is exhausted. Divide a socket wrench from a pulley.

7. Repeatedly connect installation by a bent shaft. Wires will grasp when is connected. Will bolt a layer pad back on a belt with torx the driver.

8. Begin the car and allow it to idle. Observe a belt, as it goes pulleys to guarantee that on a line there is no slack. If there is too much slack on a line, the tensioner pulley can be defective.

9. Switch off the car and close a cover.

From Car Problems

1. Guarantee that the car is switched off, and keys out of ignition. Open a cover for access to an engine compartment.

2. Follow a belt to the base of the engine a crankshaft pulley. The pulley intertwines through a layer pad. The layer pad should be removed.

3. Unscrew a bolt from a layer pad with bit torx. Pull out a layer pad from a way. Separate a wire, by unsnapping a connector.

4. Ослабьте a pulley of the tensioner with a socket wrench. Push away the tensioner to slacken a belt.

5. Move a belt from pulleys and from an engine compartment. Replace with a new belt. Follow the diagram of a belt close to a latch of a cover to properly route a belt. Don't place a belt round a tensioner pulley while picnic isn't full.

6. Push away a pulley of the tensioner with a socket wrench. Place a belt on a pulley and slowly exhaust a pulley. The belt will strain, as the pulley is exhausted. Divide a socket wrench from a pulley.

7. Repeatedly connect installation by a bent shaft. Wires will grasp when is connected. Will bolt a layer pad back on a belt with torx the driver.

8. Begin the car and allow it to idle. Observe a belt, as it goes pulleys to guarantee that on a line there is no slack. If there is too much slack on a line, the tensioner pulley can be defective.

9. Switch off the car and close a cover.

From Car Problems